Special Purpose Machine Designs We Offer for Following Industires

There Are Two Types Of Special Purpose Machines (SPMs)

The term special purpose machines refers to machines that are specifically designed and customized to meet the needs of specific customers. Standard Manufacturing Programs do not generally include tailor-made machines, which is why they are not available in ready-to-sell forms and are not included in Standard Manufacturing Programs.

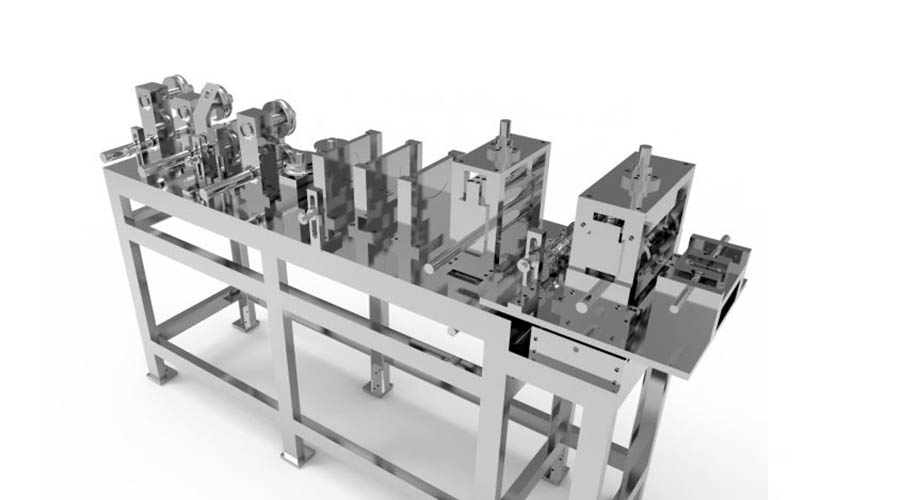

For decades, Renders India has categorically been engaged in the manufacture of special-purpose machines for a wide range of applications. In addition to our long experience in several processes, our innovative quest drives us to make exceptional special purpose machines that not only meet the needs of customers, but are also smart in the way they do so. The company has become one of the most reliable names in the domain of manufacturing excellent performing Special Purpose Machines as a result of setting benchmarks for quality. SPMs are used in a variety of areas including mixing, emulsifying, dispersing, grinding, size reduction, resin manufacturing, electrical component manufacturing, solvent recovery, and several other fields.

A Special Purpose Machine (SPM) Is A Machine That Has A Specific Purpose

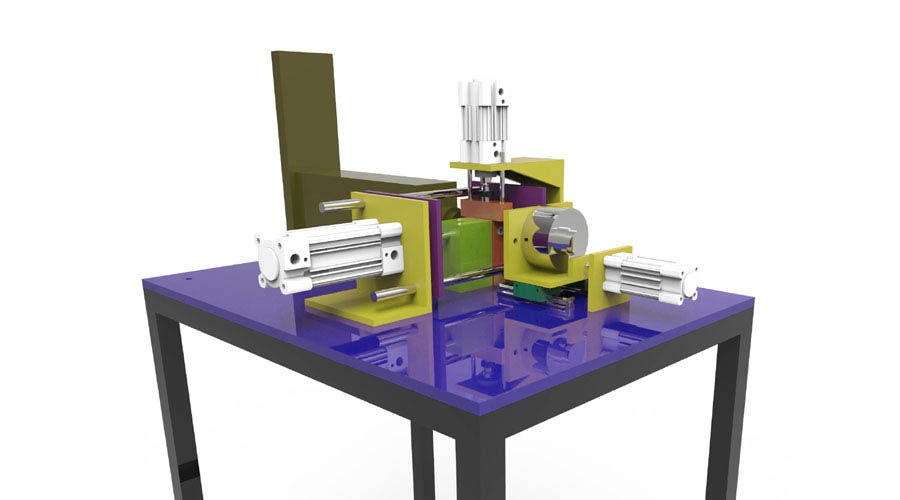

Technology is evolving at a rapid rate. Machines have become more advanced and are continuing to develop at a rapid rate. There is no doubt that automation is at its peak in the manufacturing industry at the moment. An influential role that Special Purpose Machines (SPMs) play has to do with their design and the role they play in automation. In addition to enhancing safety, a perfectly designed special purpose machine can increase production as well as produce quality products with a high level of performance. As one of the units of UMR Technologies, SPM Maker has the capability to build automated machines that are technologically sound and smart. This is according to the requirements of the client. No matter how big or how small the requirement is, we will do our very best to meet it with the help of our skilled team members. We are capable of supporting our clients from the very beginning to the final delivery of the machine. Our machines are equipped with durable and long-lasting parts.

Brief Description:

In addition to food packaging and processing, SPM Maker also offers welding automation, pick-and-place gantry systems, various automation for sheet metal and casting, articulated robot systems, etc. We provide all these services. Apart from a variety of applications these machines are calculated on exact orders where few of the users are like Endurance testing of mechanisms and products, Gauging automation for checking surfaces, thicknesses, lengths, heights via cameras or LVDTs, testing new products online, and is purposely chosen for automation.

Details:

To meet such a requirement, please tell us exactly what you need, the operations you are looking for, the long production rate, and the raw material you have available. Call or email us anytime. We will give you our 100% to provide you with the highest quality service. To offer the highest quality service, we will give 100%. Providing you with every special purpose machine possible will increase productivity with more safety. Our products will be highly reliable and ideal for production

FEATURES THAT MAKE IT SALIENT

As a result of Special Purpose Machines (SPM), very high productivity levels are achieved.

In order to minimize human errors and to reduce human exhaustion due to repeating recurring operations over and over again, SPMs are used.

As a result, these machines offer a higher level of quality and accuracy.

It is imperative to note that our Special Purpose Machines are entirely product-specific, and that each machine has been specifically designed and developed for the specific application.

A number of our SPMs are capable of handling complex operations and multiple products at the same time.

The highest level of accuracy in terms of production level, the most efficient performance, the fastest production speed, all in one machine.

A variety of materials are used in the manufacture of SmartMix machines in order to meet the requirements of different processes.

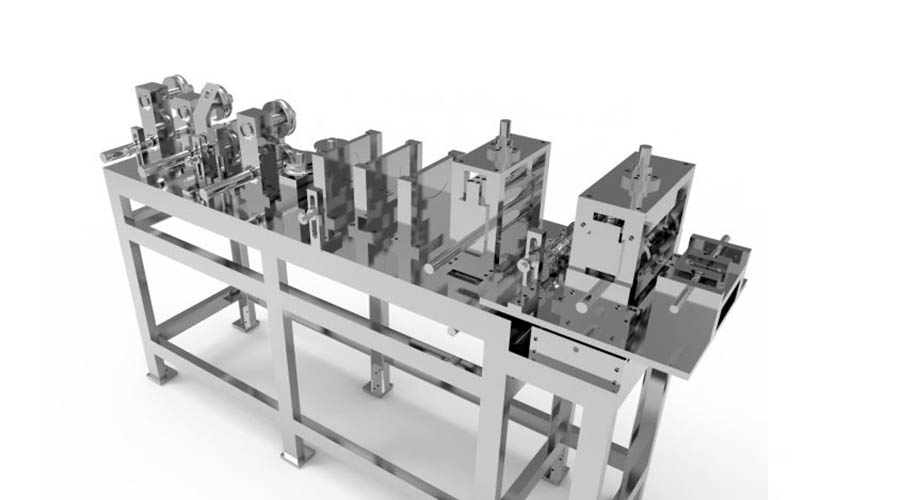

In addition, our SPMs deliver unmatched quality and superior performance thanks to our precisely calculated design and configuration specifications.

In general, SPMs are preferred over mass-produced machines due to the higher levels of productivity, quality, accuracy, and automation that they offer.

The SPMs manufactured by us are designed with a view to reducing the amount of energy consumed, the amount of production time, and the amount of material wastage.

It is imperative to emphasize that SmartMix agitators are designed and manufactured with the highest quality components.

It is our aim to manufacture all our SPMs in a way that ensures safe operation. Our safety features are sufficient to prevent any loss of property or life.

Materials and components that we use to construct our SPMs are of the highest quality, which impart maximum durability and robustness.

The availability of spare parts and wear and tear parts is easy to find

SPMs are designed and manufactured by us in accordance with the most recent engineering standards.

We manufacture and deliver our products in a short period of time.

We guarantee your satisfaction with our services.