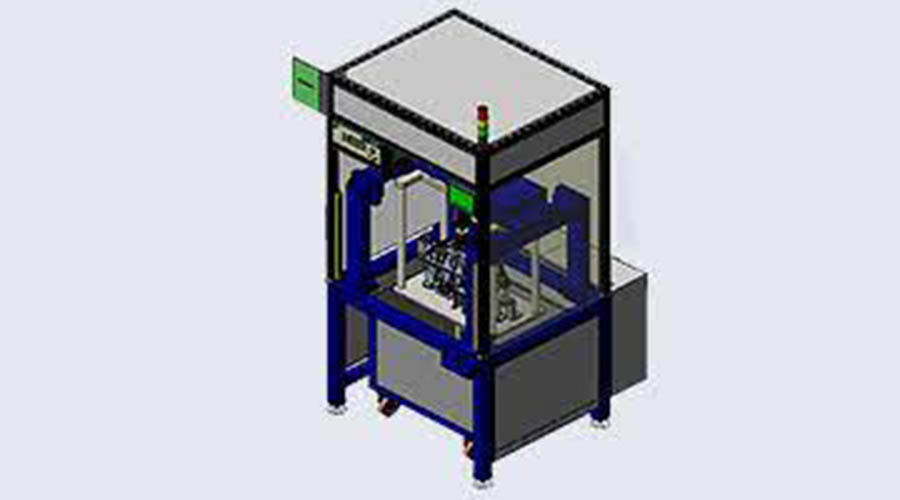

Our range of leak testing machines is designed and developed in strict compliance with industry-defined norms and standards. They are manufactured with the utmost precision and perfection in order to ensure that they are effectively tested for leakage. The machines are built with high-quality raw materials and the latest technologies. This is so that they can be made available to customers in a range of acceptable leakage rates and leak limits. This will enable them to accurately determine the amount of leakage. There is a wide range of products available from us at competitive prices.

Testing Machine for Leaks (Dry & Wet)

Ourare manufacturers and supplies a wide range of Leak Testing Machines, including Wet Type Leak Testing Machines, Dry Type Leak Testing Machines, as well as Dual Type Leak Testing Machines. As a result of the high efficiency and functionality of our products they are used in a wide range of industries, such as the Machine Tool Industry, the Automobile Industry, the Leather Industry, the Aeronautical Industry, and other general industries as well.

Having the expertise to manufacture leak testing machines (dry type) is one of our specialties. Easy to operate and low maintenance, these machines are used for air leak testing. During pressure testing, air is circulated inside the component.

Additionally, we offer leak testing machines (wet type). Under a pressurized atmosphere, the device detects leaks by dipping it in water. In most automobile components, leak tests are performed to check for blow holes and cracks. A clamp secures the component and the assembly is dipped in water. Leaks are checked by circulating air through the component. To guarantee quality and performance, we only use superior raw materials in our manufacturing process.

Machines For Leak Testiong

Make sure that your leak testing machines are reliable and cost-effective so that you can rest easy

A Leakage Testing Machine Is A Machine That Tests For Leaks

It is a procedure to check for defects or leaks in a system. This can be achieved by a variety of methods, which ensure the integrity and proper functioning of some machinery by testing for leaks. It should be noted that UMR Technology is a manufacturer, trader, and supplier of these leak testing machines to satisfy the requirements of their clients. There are many techniques by which leakage in a machine may be detected. These techniques include air decay testing, helium leak testing, and high vacuum testing. However, all of them are only applicable under certain conditions. Offering almost every major and minor machine in the fields of automation, water treatment, and bike spare parts, we also provide these leak detection machines whether it's for 2-dry leak testing or 1-wet leak testing at the most affordable price.

Our extensive range of leakage testing machines is highly demanded by industries throughout the country. They are used to control the leakage of machines of all types and to always maintain their integrity. To meet the highest quality standards, we offer world-class machines that are manufactured with the aid of modern tools and advanced technology by our expert professionals who I am very experienced in this field and have a great deal of knowledge about it.

Depending on the facility requirements or the specification provided by the client, the company offers a customized solution for the testing machine.

The Following Additional Information Is Included in The Description:

With the help of a modular approach to techniques, our product combines vast experience with a wide range of skills. The most up-to-date and effective modern data capture methods and advanced software techniques are engineered into our production environment to ensure that reliable and easy to maintain equipment that we build under expert supervision is available for our customers. The Leak Test Machines we offer are also capable of challenging the tiniest leaks with the highest level of accuracy using pressure drop & void methods. This means that even the smallest leaks can be challenged. In addition to this, we will show you a few of the leak testing methods. These are an imperative specification to consider when choosing leak testing equipment that can detect leaks

When it comes to machines that do not require a high level of sensitivity, bubble testing is used. Submerging a pressurized test object in a water tank will indicate the presence of a leak by the appearance of bubbles as the object enters the water tank.

It is possible to develop a colorimetric image by using a chemical developer that reacts with the leaky fluid. This causes a visible colour change to occur at the spot where the leak occurred.