The company's objective is to establish itself as one of the top leaders in providing top-notch engineering and technical design solutions that meet the demands of our clients, ensuring that our services are cost-effective, professional, and qualitative to meet their needs.

About TechAdroit Services

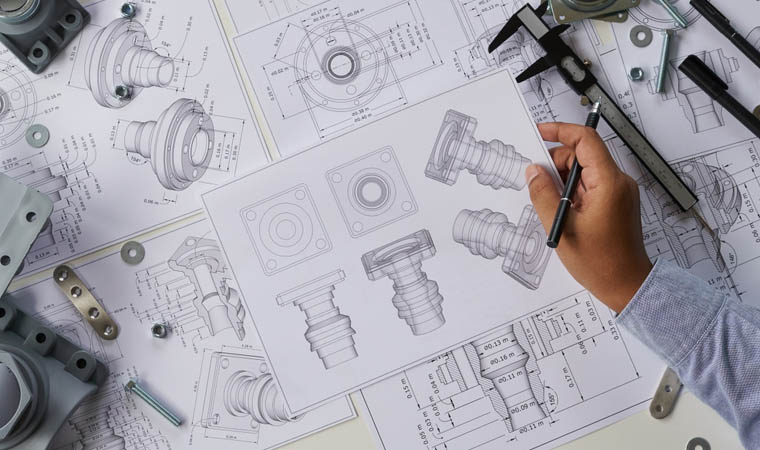

TechAdroit is one of the leading engineering and design companies in the country that offers a wide range of services. In the past few years, we have developed an impressive reputation for working with manufacturers, product design companies, and engineering consultants on the Indian market. It is our goal to provide our clients with a comprehensive range of services, including 3D Modeling Services, Mechanical Drafting Services, Product Design & Development, Machine Design & Development, Engineering Analysis, Sheet Metal Design, and Reverse Engineering services. In our team we have an experienced and well-founded team of engineers and designers who have built a close relationship with clients throughout the years. As part of our methodology, we strive to stay up to date in terms of planning, designing, and building flexibility from the very beginning. As one of the leading providers of engineering solutions, website design & digital marketing services in India, TechAdroit occupies a leading position among companies. We at TechAdroit have been committed to providing top-notch quality services at competitive market rates across all sectors and industries since the beginning of our business in Since. As a result of our services, numerous companies in Pune and Mumbai are currently using our services. Because we have built a stellar reputation for ourselves through the successful completion of projects within the scheduled time frame, we intend to become the market leader in the near future. A dedicated and talented team based in the fields of engineering and online marketing. With experts in cutting-edge CAD systems, SEO, SMO, PPC, and more, our team of professionals can cruise you to success. It does not matter if you need a 3D walkthrough of your construction project, help with the design and development of products, 2D drawings and 3D models of your project or a responsive website to promote your business to the masses via the Internet, we have everything you need

AUTOMATED MACHINES : EXAMPLES

It's challenging to give specific examples of how automation can be used across a factory since there are so many types of equipment. Here are some general examples.

In robotics, robots perform tasks that humans cannot do, or are too precise, or must compete with manual labor costs. Precision is required for these robots to operate successfully, which requires machine vision and EOATs.

With advanced software tools, automated machines are able to communicate with the people running them, work efficiently, anticipate changes in demand, and create error-free work.

Robots and machine vision technology often work together because machine vision technology allows for better precision when handling materials or guiding tools. In the future, machine vision wilthe key to theey to most successful automated factories.

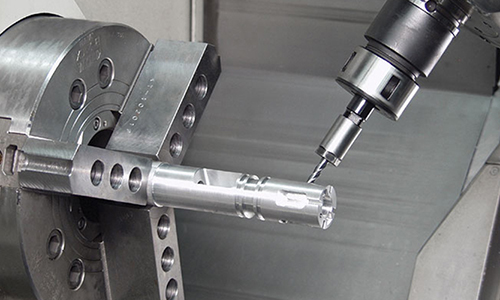

The use of CNC machines in automated systems is accomplished by retrofitting existing equipment with CNC machines. Older machines tend to be difficult to retrofit, but manufacturers are discovering they can use their legacy equipment in more efficient ways - and at a lower cost.

Increasingly sophisticated computer numerical control (CNC) machines can automate tasks that once seemed impossible. Combined with the right software, these systems can be used to effective effect when paired with other types of automation.

Due to their flexibility and potential for large-scale production, additive manufacturing (AM) and computer-aided design (CAD) are becoming more prevalent in factories around the world. As technology advances, AM will soon become an integral part of many other factories.

AUTOMATED MACHINES: WHAT ARE THE BENEFITS?

You will see improvements in many areas of your manufacturing process if you design your machines for easy automation. Here are a few: Enhances productivity-Increased output per shift is possible for manufacturers. Reduce product defects-When a machine is automated, there is no need for manual inspections or interventions, so errors are greatly reduced. Saves labor costs-By automating a machine, you can reduce labor costs by reducing the need for human intervention. Enhances agility-You can adjust your manufacturing process on the fly with an automated manufacturing cell. Production levels can be quickly increased if demand changes. Enhances flexibility-Using an automated manufacturing cell, you can switch between products or tasks easily.