HOW DOES A ROBOT CELL WORK?

The topic of production flow innovation and improvement is a key one for many entrepreneurs who are considering strategies to innovate and improve the production flow of their organization. On the surface, robotic cells appear simple, but they involve complicated projects and highly sophisticated solutions. These solutions, which are often designed to make the production flow of each company as smooth and efficient as possible.

ROBOTIC CELLS: NEW WAYS TO WORK

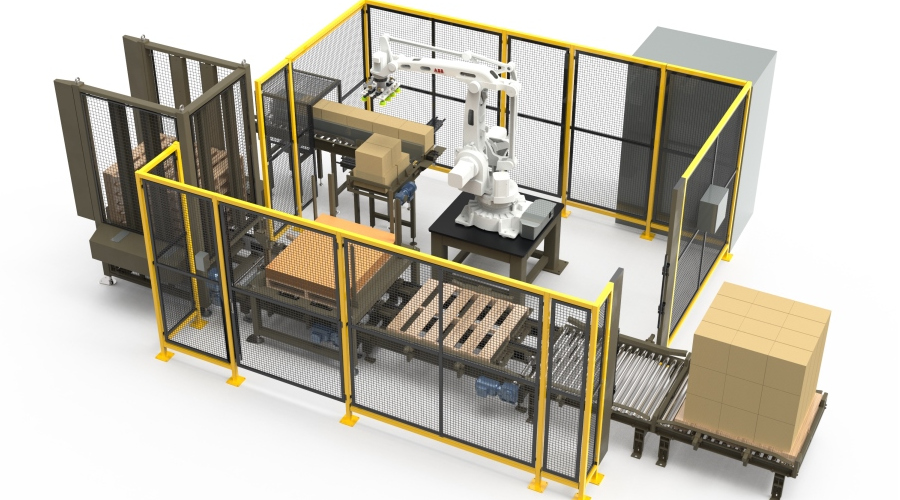

We can answer the question "what is a robotic cell" by defining one: a robotic cell - or robot cell or robotized cell - is a set of machines that are organized within an automated work cell containing one or more programmable robots. This robot can maximize, speed up, and simplify a complete production module and achieve high levels of repeatability.

High autonomy characterizes these automated systems. Also, robots can cover night shifts and holidays. No one gets sick or misses out on a holiday.

Although they may require a substantial initial investment, they can provide a quick Return on Investment (ROI), which is crucial for managers. Well-designed robotic cells have a payback of less than a year.

In Many Production Sectors, Robotic Cells Automate Different Operations, Such As:

Tend machines

It is assembled

Handling of data

In palletizing

In welding

The final steps

In any industrial field (fashion, automotive, aeronautics, mechanics, pharmaceutical, food, etc.), robotic automation finds application. Any task performed by a robotic cell will be precise and reliable. Besides being highly efficient systems, robotic cells are extremely flexible: you simply have to reprogram the robot(s) when you change the format to be processed. In addition, robot cells can be quickly and efficiently converted from one processing type to another.

A ROBOT CELL'S "EYES"

A robotized cell can also be equipped with artificial vision systems that make it possible for industrial robots to be autonomous because they can see. When equipped with AI (Artificial Intelligence), they can even decide what to do. As a result, robots can be programmed to read codes and locate objects of any shape, size, location, or color. These control systems enable robots to pick up and load workpieces stored in bulk inside trays or trolleys into the machine.

ROBOTIC CELL SAFETY BARRIERS

Robots that reach high accelerations and are heavy perform potentially dangerous operations inside robotized cells. As a result, operators should take precautions when loading/unloading, performing maintenance, or responding to emergencies near the robot. Two types of safety devices are included in our cells: There is a metal structure surrounding the entire work area, with an alarm door allowing entry after the robot has been deactivated. Laser barriers are strategically placed inside robotic cells with laser sensors. By sensing the presence of a foreign body, this sensor slows down or stops the robot (and therefore the whole cell) depending on how close the object is and immediately restarts it when the individual is far enough away.

Systems for picking and placing

Pick and place machines of all types are made by us. Gantry systems can be operated delicately or heavily. We can either custom build a system or use robots With our systems and processes, we help our manufacturing sector customers build better quality products and improve their productivity.

Robots in the Gantry?

In addition to being called a Cartesian Robot or Linear Robot, a Gantry Robot is an automated industrial system. In gantry robots, linear paths form a three-dimensional cubic space in which they can operate.

GANTRY ROBOT USE: WHEN?

Automating tasks that demand high repeatability can be done with any robot. Automation optimizes production, reduces injuries, and allows employees to focus on other tasks such as quality control. Specifically, a gantry robot is ideal when a large or heavy object needs to be manipulated and handled with precision or the task involves a large area of manipulation. Various sizes, strengths, and configurations are available for Sage Gantry Robots. A small gantry robot is similar in size to a small room, while a large gantry robot could be as long as a football field and as wide as fifty feet or more, depending on end-user facility constraints. Several tons to a few pounds of payload are possible.

In addition to pick and place applications, Gantry Robots have been used for:

PALLETIZATION OF PRODUCTS Depalletization Unloading machines THE PROCESS IS IN PROGRESS THIS IS THE END OF THE LINE HANDLING OF MATERIALS TENDING OF MACHINES SORTING AND STORAGE OF INFORMATION PACKING AND STORAGE We're always finding creative uses for gantry style approaches at Tec Adroit. Contact our Applications Engineering team for a complimentary consultation if you are unsure whether a gantry robot is right for you.